When it counts, count on us.

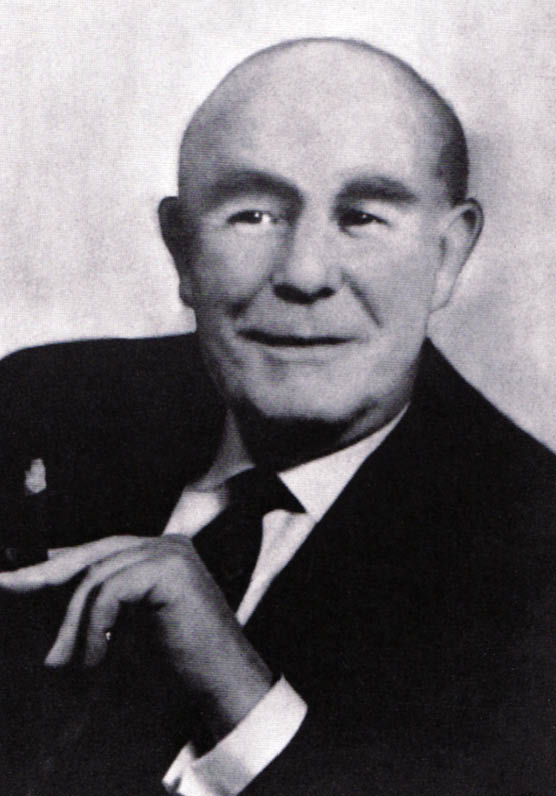

A success story that’s over 100 years in the making. An international team with over 30,000 employees. And a future that we can create together – Carl Kaefer couldn’t have imagined any of this in his wildest dreams. Today, we look back not just on a fascinating history, but also towards an exciting future full of innovation, ideas and engaged people. Because they are the ones that make KAEFER into something special.

was the peat

The idea of using peat for insulation inspired Carl Kaefer 1918 to found our company

TYPICALLY

1918 Establishment

"In the wide-open landscape of Poggenmoor…“

Workers cutting peat, postcard 1911

new avenues

in insulation

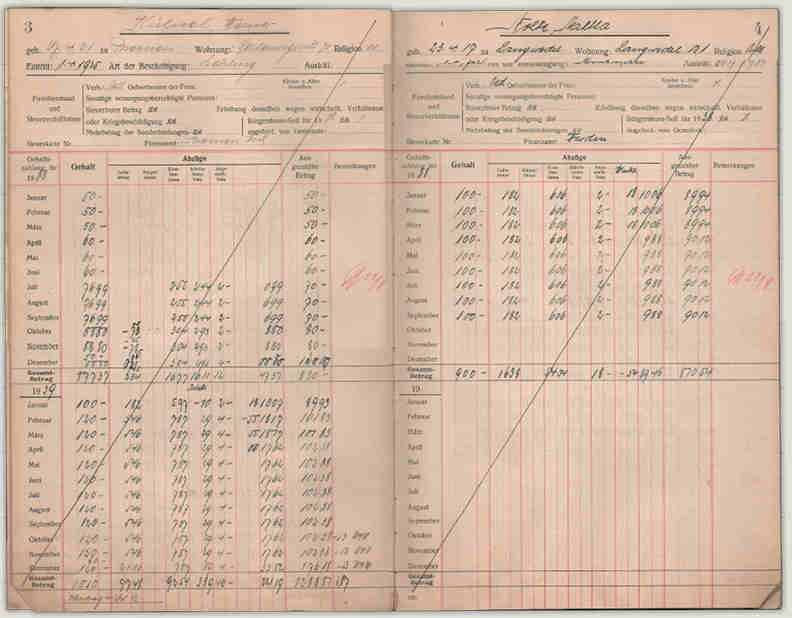

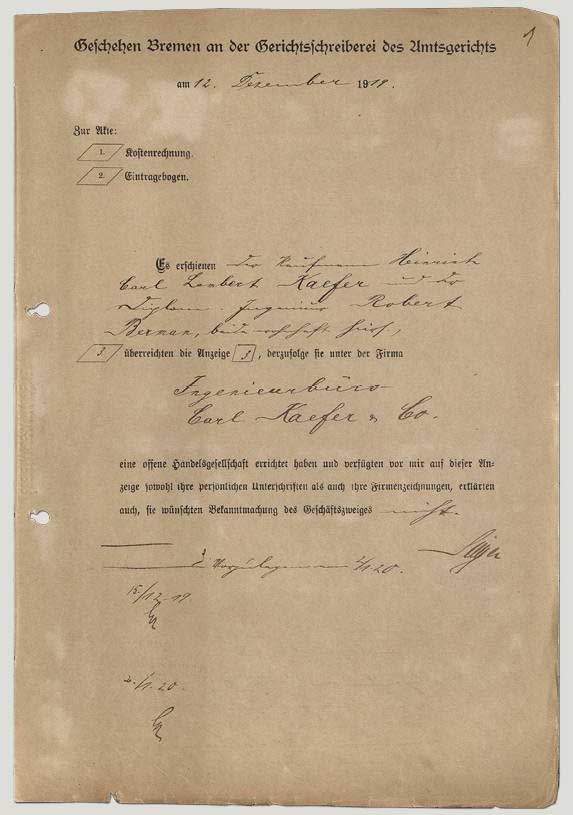

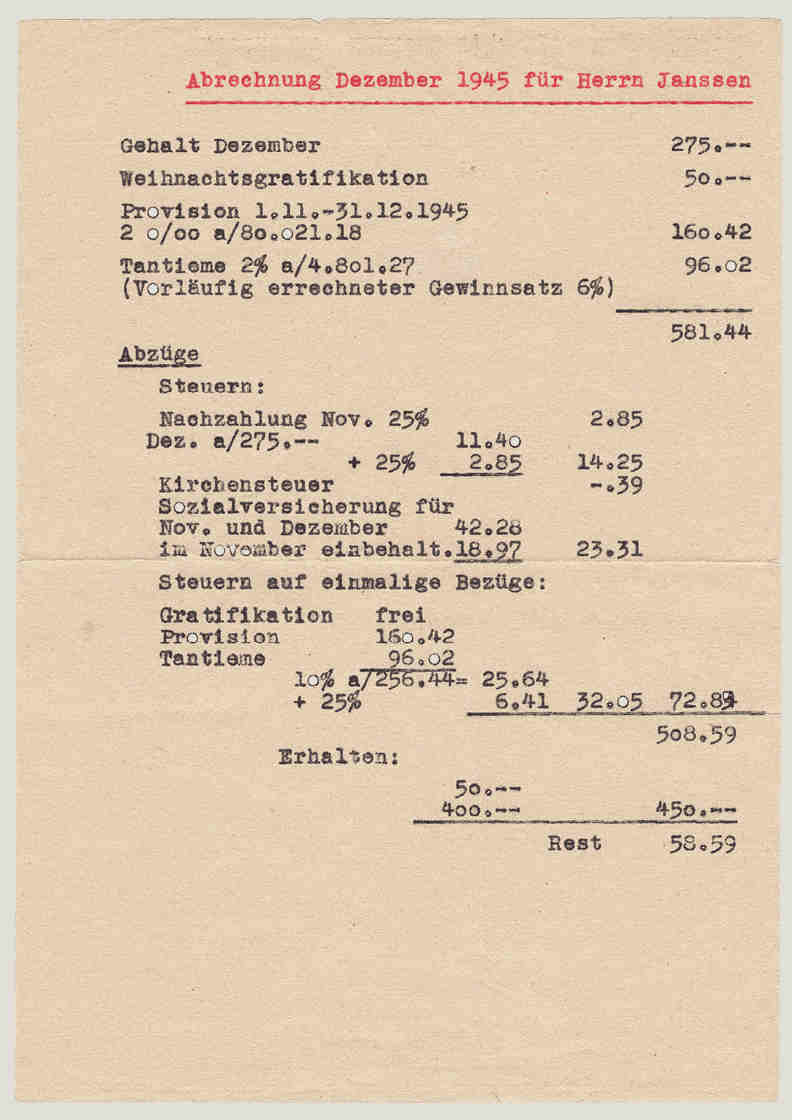

January 1920: entry of ‘Ingenieurbüro Carl Kaefer & Co.’ into the commercial register in Bremen. Heinrich Carl Lambert Kaefer and Robert Berman are managing partner

Official entry in the commercial register, 1920

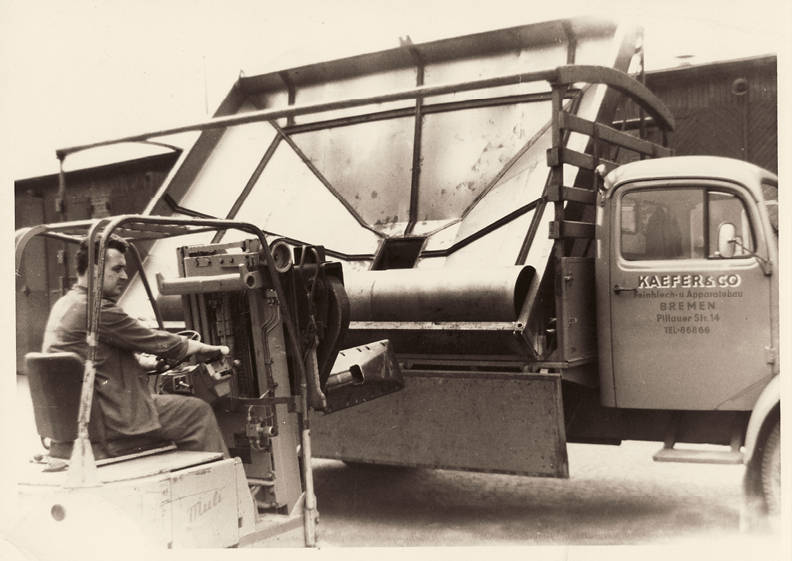

First major contracts for insulation work on ships. Five insulation fitters are hired, and the first truck is purchased

KAEFER grows and employs 15 skilled workers in 1923

At times there are around 300 KAEFER fitters working at the Blohm & Voss shipyard in 1926 and construct the “Europa” for the northern German Lloyd as well as the “Bremen” for AG Weser – both the most modern turbine passenger ships in the world

TYPICALLY

1926 full-time contract

„Work was only available when orders came in.“

As remembered by Erich Westphal

The proud team in front of KAEFER’s first truck

The first branch in Wesermünde-Geestemünde is entered into the commercial register in Hamburg 1928

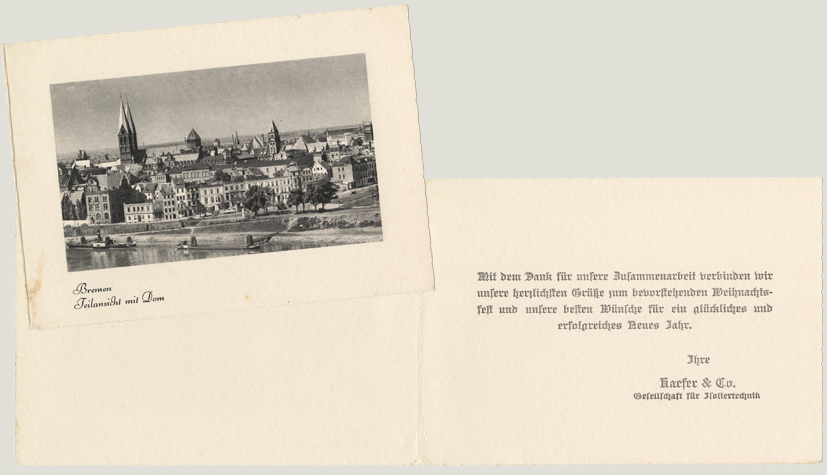

KAEFER Christmas card 1929

worldwide

economic

crisis and war

The effects of the economic crisis don’t pass the young Carl Kaefer & Co. company by. The branch in Wesermünde is closed again in March 1930

TYPICALLY

1930 „For your wife“

„Carl Kaefer could be very charming.“

As remembered by Robert Renken

Robert Berman leaves the company in 1933 because of his Jewish heritage. Berman and Kaefer delay the sale of his share of the business until 1936. Robert Berman retains a consulting role at the company

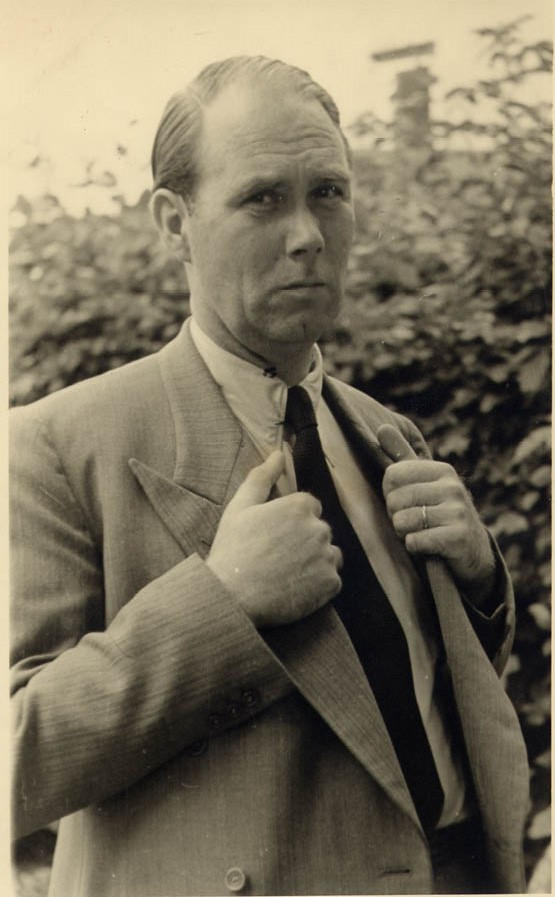

Carl Kaefer with other Bremen merchants

TYPICALLY

1933 Friendship

“I am reluctant to see my friend depart…”

The first apprentice begins his training 1935 at KAEFER

KAEFER employs 60 fitters on average

In 1936, the company employs 70 people

70 percent of total turnover in 1936 is in insulation, fitting and in stone and woodwork. 30 percent is made with the trade in insulation materials

As part of his search for a successor, Carl Kaefer meets Heinz Peter Koch in 1938, who works as an executive assistant and technical merchant at Siemens in Berlin

The beginning of the war 1939 sees an increase in defence spending in the Third Reich. KAEFER works on marine jobs and continues to develop insulation mats

industrial plants

New branches are established in Emden, Oldenburg and Elberfeld in 1940 and workshops are set up in Swinemünde and Grevesmühle

Carl Kaefer and Heinz Peter Koch enter into a partnership agreement on the 28th June 1941. The company is converted to a limited partnership

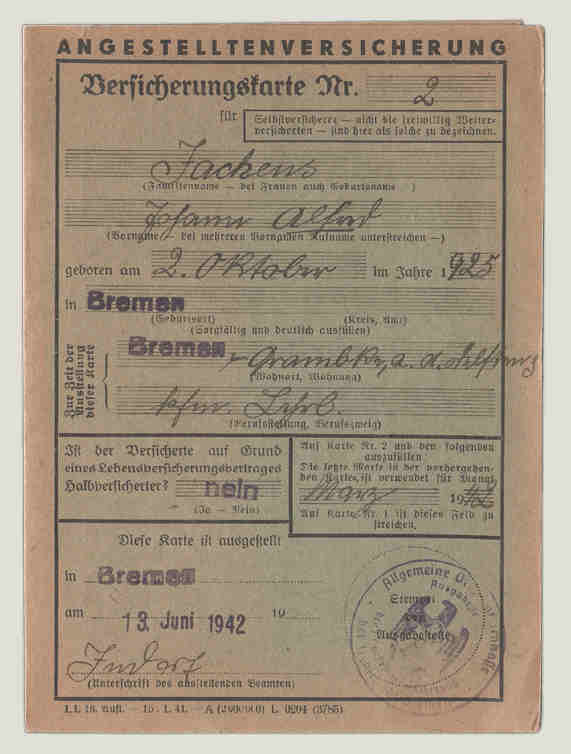

1942 sees the establishment of a KAEFER provident fund to protect employees. Shares of the limited partners profits maintain the fund. Employees are not required to contribute

‘Carl Kaefer & Co.’ works in aircraft construction at Weser-Flugzeugbau in 1944

Carl Kaefer dies on the 11th April 1944 in Rotenburg/Hanover after a long illness. His widow Wilhelmine is his heiress

In 1944, 177 people work at ‘Carl Kaefer & Co.’ on average

The branches in Hamburg and Bremerhaven are being destroyed in 1945

1945, towards the end of the war, only around 80 people work for the company as many were drafted into the military. Heinz Peter Koch was also drafted and is captured in the Netherlands. He is then released on the 19th of October. In the winter of 1945, approximately 15 employees restart work in a temporary office in Bremen

TYPICALLY

1945 New start

„Then they return as released prisoners of war…“

As remembered by Heike Ernst

TYPICALLY

1945 Stealing coal

„Could anyone sort anything out?“

As remembered by Edith Ader

Material shortages dominate in the years after the war

KAEFER celebrates its 30-year anniversary on 1st October 1948 in Bremen at the “Erwin Malorny” restaurant with Wilhelmine Kaefer and the company’s employees. This will later become the site of the insulation mat workshop for the Bremen branch

First trials with insulation cladding take place in 1948

Industrial insulation work in the 1940s

TYPICALLY

1948 Without pay

„I remember how we were without pay for just one week…“

As remembered by Erika Tiedemann

the “economic

miracle”

First contract in the oil industry 1950: major cladding work is done at the new Mobil Oil refinery in Bremen Oslebshausen. These are prefabricated at the KAEFER workshop

TYPICALLY

1950 Sheet metal premiere

„Mr. Koch spotted the trend ahead of time.“

As remembered by Folkert Oldenburger

Robert Berman’s son, Emil Berman’s compensation claims are settled on 25th September 1951

Employees of the mattress workshop in Bremen

In 1951, KAEFER brings a patented, weather-independent insulation system made from hard foam with seawater-resistant aluminium covers as an inner cladding to the market

The German fishing and merchant fleet is built up in 1954. KAEFER offers insulation for refrigerated vessels. Further patents are filed

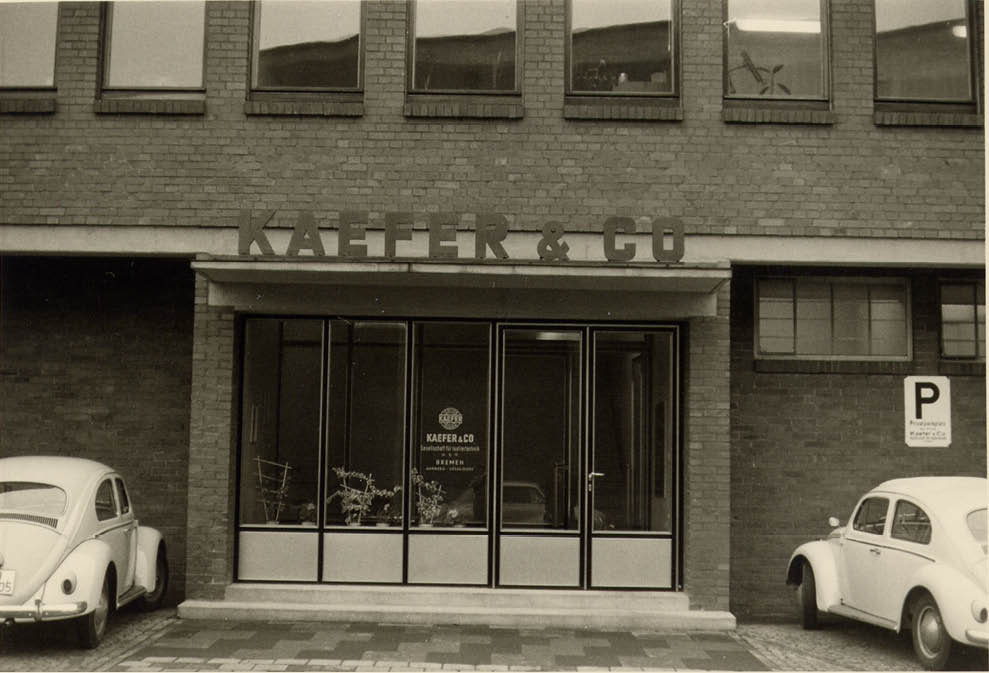

In 1956, KAEFER moves to Pillauer Straße/Getreidestraße in Bremen, where the company is located to this day

Blue and white-collar workers are competing in the “Soccer Championship” in 1955 (Heinz Peter Koch, 2nd from left in upper row)

TYPICALLY

1956 “Wild carriage”

„Renken’s homemade potato fritters were particularly popular.“

KAEFER registers a patent for “metal cladding for pipe insulation” in 1957

Polyurethane foam is processed as of 1959 at KAEFER and used as insulation

„MADE IN GERMANY„

Entrance branch office Bremen, 1961

For the first time, KAEFER employs over 1,000 people in 1961

Major contract at the Esso refinery in Cresier, Switzerland. In 1964, KAEFER benefits from international recognition and attention as a result of the seamless execution of the project

TYPICALLY

1960's Industrial insulation

“Before we started with industrial insulation, we just worked in ship construction.“

As remembered by Arno Recknagel

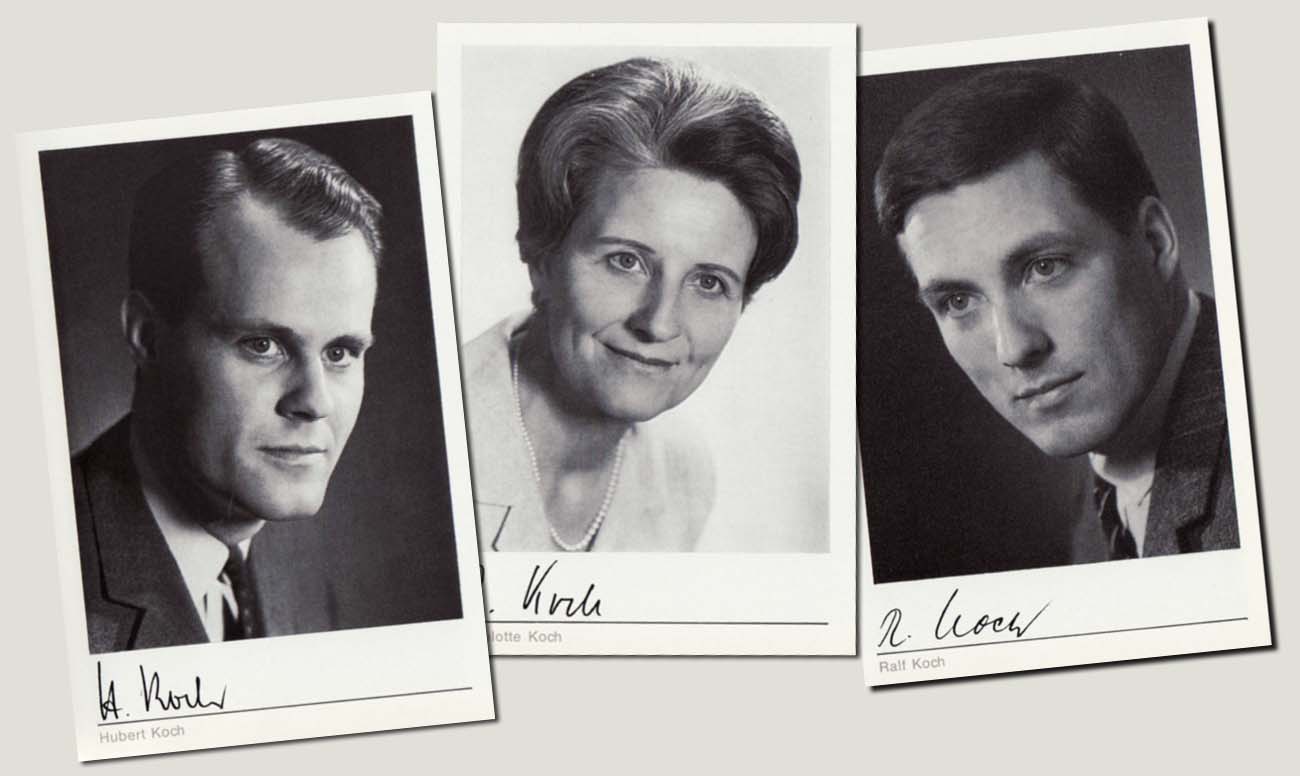

Heinz-Peter Koch dies aged 57 in 1965. His wife Annelotte takes over the running of the company with sons Hubert and Ralf in 1966

Central administration and the branch office are divided from one another in Bremen 1967

TYPICALLY

1968 Support

“If marks are poor and exams are at risk…“

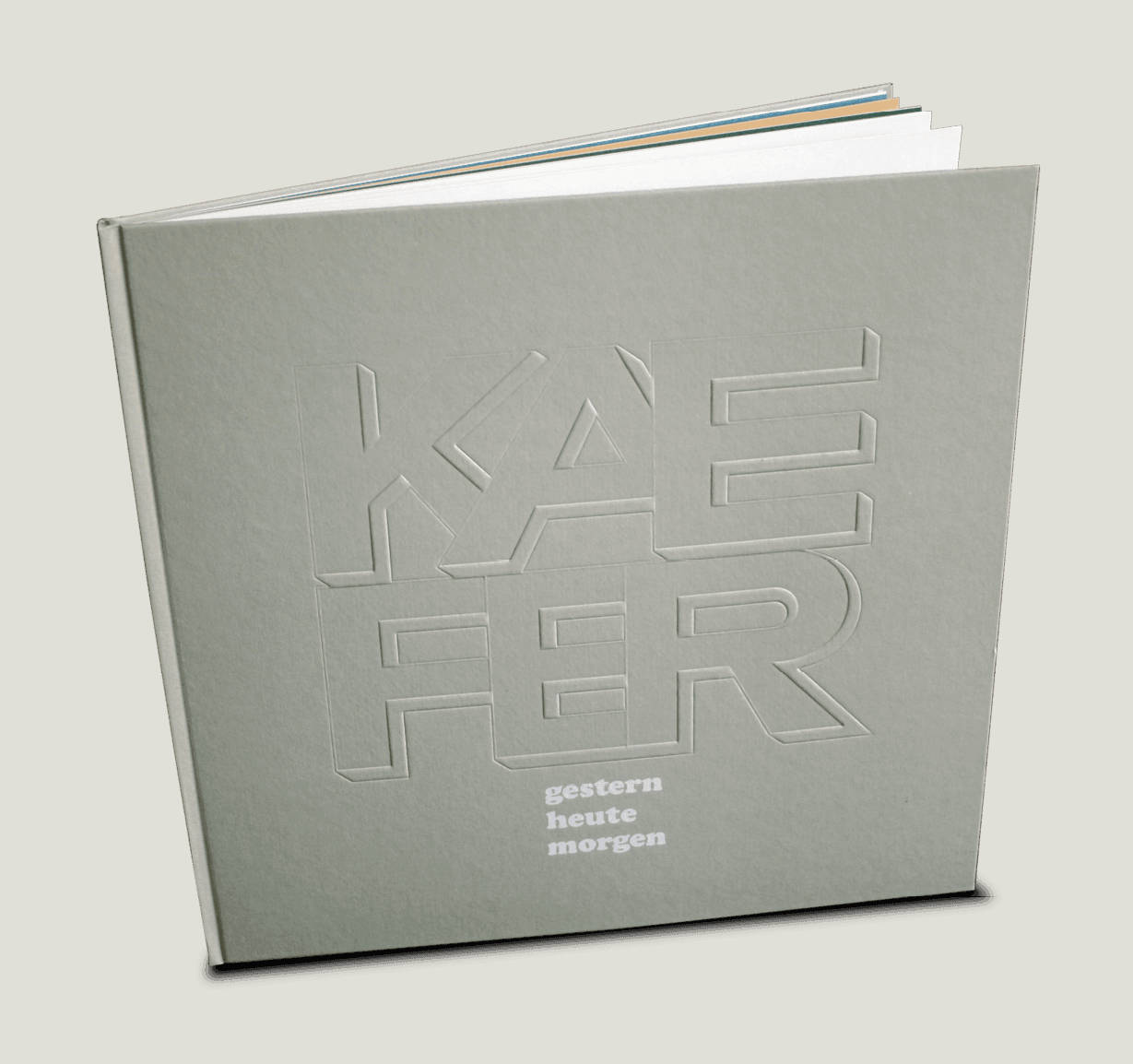

KAEFER celebrates its 50-year anniversary with a large party at Getreidestraße on 1st October 1968. The book “KAEFER Isoliertechnik– yesterday, today and tomorrow” is published

further – inspired

by the Olympic Spirit

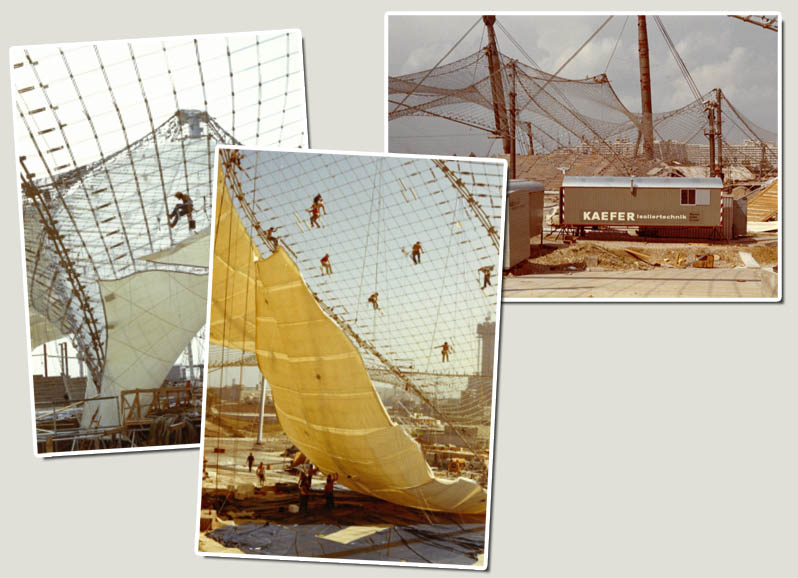

KAEFER equips the swimming and sports hall at the Olympic stadium in Munich with a translucent ceiling in 1972

TYPICALLY

1972 Olympics

“Couldn‘t the insulating ceiling be made of bundled plastic straws?“

As remembered by Ralf Koch

First insulation of an LNG carrier 1973: KAEFER works on the “Venator” tanker for the Moss shipyard

In 1974, KAEFER receives the largest acoustic contract to date. Worth over 10 million DM, the client is the University of Bielefeld

What’s taken for granted today wasn’t in the 70s: the first female apprentice starts at KAEFER in Germany in 1974

TYPICALLY

1974 Girl power

„Jutta Sonnewald is the first woman to start training at KAEFER.“

As remembered by Carsten Wrede

KAEFER installs thermal insulation in 1976 at the new UNO city superstructure in Vienna

The first insulation of a liquefied petroleum gas (LPG) tanker: shipbuilders Wärtsilä in Turku, Finland contract KAEFER in 1976 to insulate seven LPG ships

KAEFER engineers develop the basis for cryogenic insulation systems in 1978

KAEFER finds a home in the offshore sector as well, outfitting a Phillips Petroleum Company drilling rig in the Norwegian Ekofisk oil field in 1979

to the world

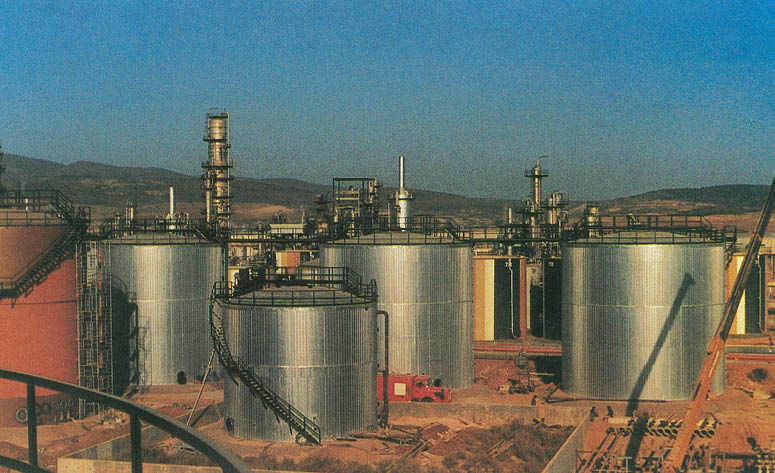

IIn 1980, colleagues from Austria are responsible for engineering, material supply and the fitting of over 200,000 m² of thermal insulation for a refinery in Arzew, Algeria

This film is in English language.

KAEFER introduces computerised payroll accounting in 1981. One year later, the entire accounting department makes the switch

Noise

emissions from train tracks are substantially reduced 1981 with

KAEFER’s help in the expansion of Munich’s subway system: mats placed

underneath gravel have excellent sound-absorbing qualities. KAEFER is

responsible for preparation for fitting and the fitting itself

KAEFER is also active in two large scale projects in southern Germany 1982: the new construction of an ethyl plant at the German Marathon Petroleum refinery in Burghausen as well as the construction of the nuclear power plant at Grundmemmingen

KAEFER introduces computerised payroll accounting in 1981. One year later, the entire accounting department makes the switch

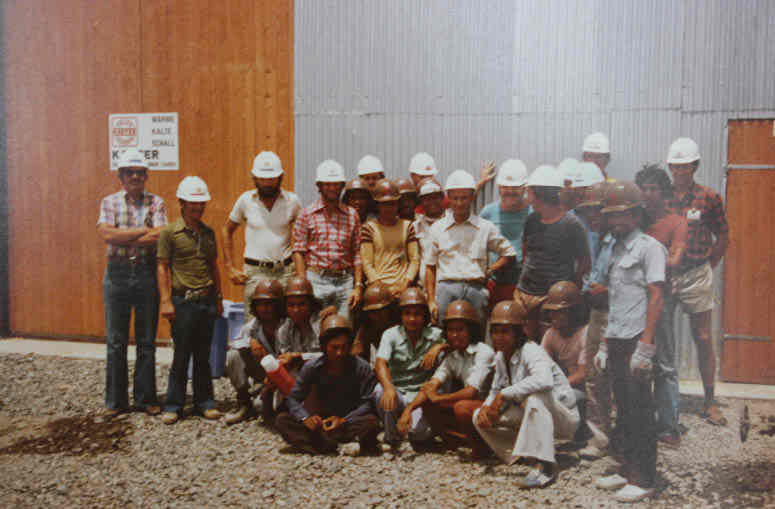

KAEFER takes part in the expansion of the natural gas liquefaction plant at Arun in Sumatra once again in 1982. KAEFER was already there at this large-scale construction project when the first phase was completed in 1978

TYPICALLY

1982 Delay

„I’m terribly sorry, but our ship is late.“

As remembered by Hartmut Kolkowski

TYPICALLY

1982 Plattdeutsch

„During the Arun project, many Telexes…“

KAEFER celebrates 65 years in business on the 1st of October 1983

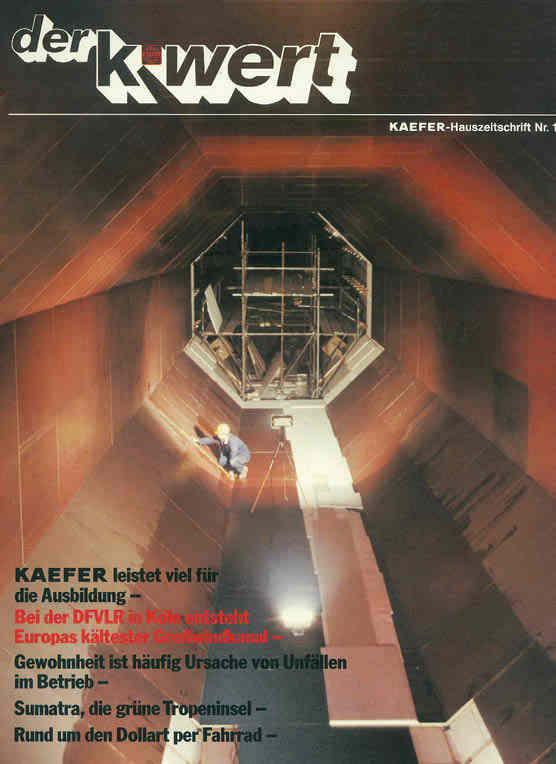

In 1984, KAEFER is involved in the refitting of the German Research and Development Institute for Space and Aeronautics’ large-scale wind tunnel in Cologne. The tunnel is converted from subsonic to sub-zero temperature operation

The first edition of “K-WERT”, the employee magazine, is published 1984

One in five prospective industrial insulators in Germany do their apprenticeship at KAEFER in 1984

TYPICALLY

1984 1st K-WERT

A magazine is launched

Introduction of the first company suggestion scheme, which makes individual employees’ ideas available to all as of 1985

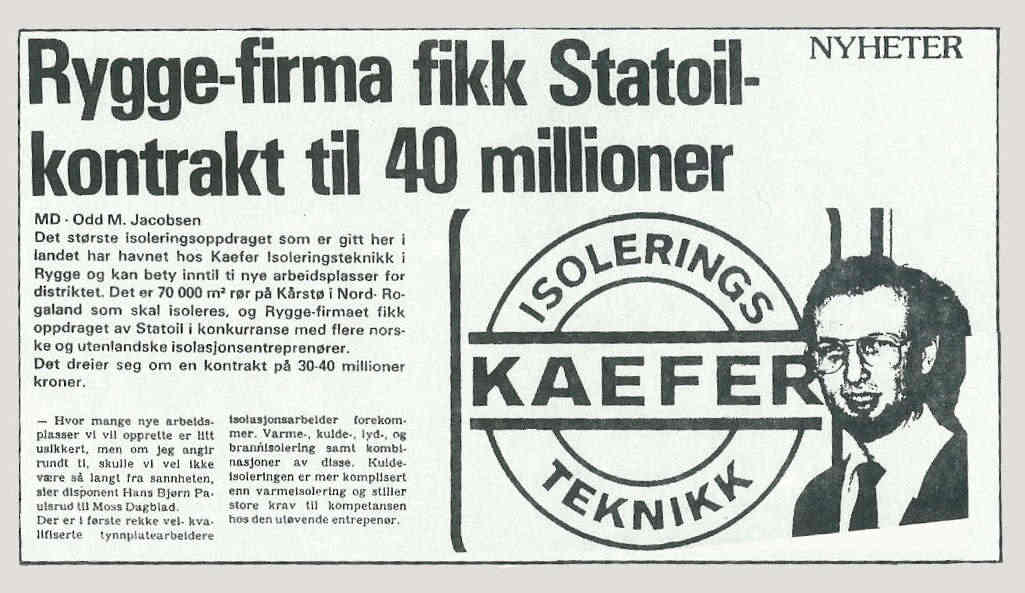

Large scale contract in Norway 1985: KAEFER is involved in insulation work for the new construction of a natural gas liquefaction plant in Kårstø. 350 KAEFER employees are working there at peak times

The construction of passenger ships sets sail in 1986: insulation work is performed on the “Karl Carstens” (photo) and “Peter Pan” ferries

TYPICALLY

1985 Dedication

„Hermann Klezath heads to the airport…“

As remembered by Hermann Klezath

The ‘operational safety’ department is founded in Germany in 1987

KAEFER employees from Belgium prepare sheet metal and coordinate local personnel in Moso, Burundi in 1988, who fit the insulation for two boilers at a sugar factory

KAEFER employees insulate several fermentation and storage tanks at a brewery in China over the course of 13 months in 1988

The opening of the East German border 1989 allows KAEFER to expand its business into the new German states

KAEFER manufactures and installs an interior cryogenic insulation system for the European Transonic Wind Tunnel in 1992 – the world’s most modern testing facility for supersonic flight

Queen Elizabeth II. is visiting the construction of the ETW

TYPICALLY

1992 Wind tunnel

„The tunnel only worked with excellent cryogenic insulation.“

As remembered by Arno Recknagel

In 1992, KAEFER secures a contract for the insulation of the steel container at the German Neumayer II research station in Antarctica

Kvaerner Masa Yard contracts KAEFER in 1993 to insulate the spherical transport tanks and deck lines on four 135,000 m3 LNG tankers for the Abu Dhabi National Oil Company (ADNOC). The work is completed in 1997

KAEFER celebrates its 75-year anniversary in 1993 with a ceremony at the upper city hall in Bremen and an exhibition

Movie on the occasion of the 75th company anniversary

KAEFER sets up an advisory board in 1994, consisting of external as well as family members to advise management and all remaining shareholders

In 1994, KAEFER is responsible for the complete cooling insulation of devices and pipes for the world’s largest steam cracker built in one unit in Antwerpen for BASF. 138 tonnes of PU in-situ foam and 66,000 m² of zinc-coated steel are processed

TYPICALLY

1995 End of an era

„Those cheers turned into a standing ovation...“

Separation of capital and management – Annelotte and Ralf Koch withdraw from the daily management of the company and pass duties on to Norbert Schmelzle in 1995

Norbert Schmelzle

TYPICALLY

1995 New CEO

„P&L is the highest abstraction of human passion…“

KAEFER Isoliertechnik GmbH receives DIN EN ISO 900 certification 1996, followed one year later by SCC certification

The German KAEFER Group website goes live in 1997

KAEFER plans, manufactures and delivers cassette insulation for the primary cooling circuit at the Brazilian ‘Angra II’ nuclear power plant in 1997. KAEFER employees also supervised fitting on site

KAEFER takes care of fire protection, heat and acoustic insulation and installs roofs and walls in the process of lengthening the “Norwegian Wind” and “Norwegian Dream” cruise liners 1998 at the Lloyd shipyard in Bremerhaven, Germany

TYPICALLY

1997 Angra II

„During our tour of the containment...“

As remembered by Henry Kohlstruck & Günther Ahlers

KAEFER removes asbestos in pipes, interior walls and facades in 1998 during the renovation work at the “Centre National d’Art et de Culture Georges Pompidou” in Paris, France

KAEFER is responsible not just for the insulation of residential modules on the IVANA drilling rig commissioned by INAGIP at the Viktor Lenac Shipyard in Rijeka, Croatia, but also delivers all of the interior outfitting in 1998

Since 1999 modern simulation software based on the finite element method is used to calculate complex insulation problems

local strength

Operational safety, the reduction of accidents and the quality of incident reporting is the focus of the ‘Safety Year 2000’ in Germany.

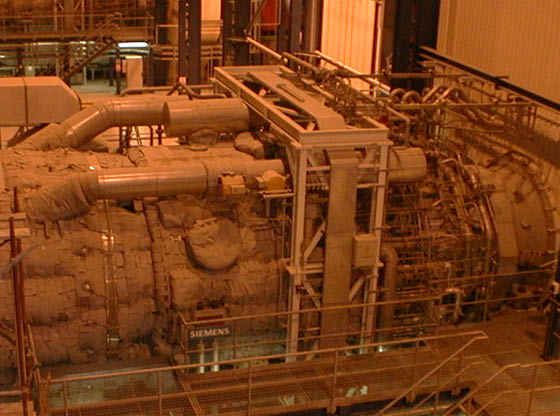

KAEFER registers a patent for new interior insulation of gas turbines. The new KAEFER construction uses a system of flat profiles and rails instead of heavy bolts. This is easier to fit and provides cost reductions of up to 20%.

The biggest contract in KAEFER’s history to date in shipbuilding is realised: the building of the “Olympic Voyager” fast cruise liner starts and work on the “Olympic Explorer” begins as well.

This film is in English language.

Starting the production of flexible insulation mattresses for gas turbines. Manufactured in Abu Dhabi in a specially designed workshop.

Successful project completion on the world’s largest floating gas platform off the coast of Norway. KAEFER is responsible for the complete thermal insulation and fire protection of the “Åsgard B’s” platform and pipes, as well as the fire protection and interior outfitting of offices and residential quarters.

KAEFER becomes market leader in France through the takeover of WANNER SAS and WANNER Marine SAS from Vinci.

KAEFER is responsible for the fire protection elements in the ceiling of Hamburg’s Elbe Tunnel in Germany.

TYPICALLY

Underneath the river

„The most elaborate fire protection system ever implemented in Europe.“

KAEFER showcases its abilities with two large-scale projects in Vienna. The redesign of the IBM House on the Danube canal and the expansion of the ARES Tower office building are impressive and attention-grabbing construction ventures.

The “Ulysses” ferry receives the ‘Cruise & Ferry Award 2001’ for features such as the observation deck, which was realised by KAEFER in Finland.

Introduction of the central apprenticeship system in Germany. All commercial apprentices are trained in Bremen.

KAEFER undertakes insulation work on a Dow Chemical ethyl plant in the Netherlands and insulates a new block at an LNG facility in Borneo in Southeast Asia

To expand its position in the Eastern European market, KAEFER takes over the polish company TERMOIZOLACJA and its 600 employees.

INSTA-LAG® and TIPS® are specially prefabricated products for the insulation of pipes and heating boilers that can reach temperatures of up to 650 °C. These are introduced to the Australian market.

Award from the Karl Nix Foundation in Bremen: a KAEFER apprentice is given the Best Chamber of Trade Examinee prize.

KAEFER Academy: the Junior Executive Academy (now called the Junior Leadership Programme) is established to identify, support and promote qualified talent.

KAEFER receives a major contract from Shell and BP in South Africa: KAEFER is now responsible for maintenance, insulation, scaffolding and surface protection at the new SAPREF refinery for the next five years.

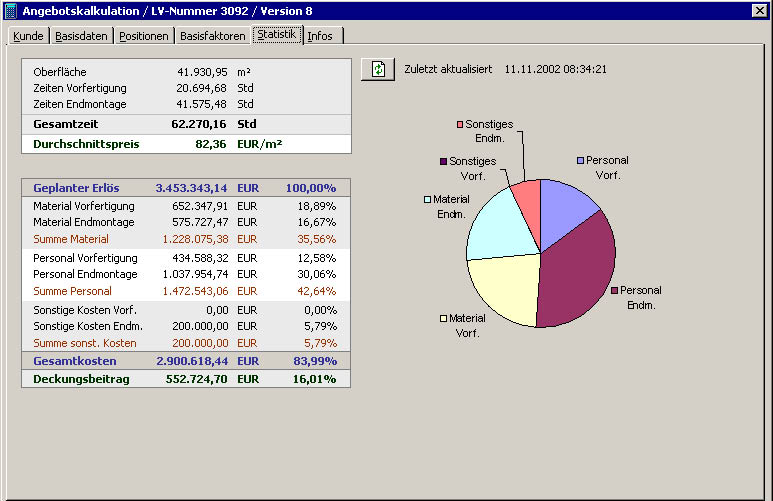

KAEFER’s own ‘I\K\A\R\U\S’ calculation software is developed. This stands for insulation, calculation, handling, invoicing and SAP integration. It makes the efficient calculation of projects possible.

KAEFER in Abu Dhabi becomes the first company in the UAE to receive ISO 9001 and 14001 as well as OHSAS 18001 certification.

Third place at the European Championship for Industrial Insulators goes to a KAEFER employee.

KAEFER know-how for China: during the building of two power plant blocks in Lianyungang, KAEFER provides its special knowledge to a Russian company under license and undertakes engineering work, construction and some parts of manufacturing itself.

World premiere in the Weser tunnel: a tunnel robot developed by KAEFER is used to fit passive fire protection for the first time during the construction of the Weser tunnel.

Award from the Karl Nix Foundation in Bremen: a KAEFER apprentice is given the Best Chamber of Trade Examinee prize.

KAEFER boards cruise liners in France: The “Queen Mary 2’s” 7 km-long cooling networks is insulated. On the “Crystal Serenity”, a total of 6 km of pipes and 2,500 m² of ventilation shafts are insulated in accordance with the strictest fire protection requirements.

KAEFER insulates pipes and channels in Lisbon’s European Cup football stadium

KAEFER installs KAEMOBIL partition systems made of metal in BMW’s production facility in Leipzig, Germany. Mounting the 30-metre-long, self-supporting F30 cabins was particularly challenging.

KAEFER in Finland is responsible for the development of turnkey solutions for Kværner Masa shipbuilders’ “Mariner of the Seas”.

Start of the ‘Snøhvit’ project, the largest single contract in the company’s history till then: in cooperation with Aker Kværner, KAEFER develops an integrated service package for the construction of an LNG plant in Norway for Statoil.

TYPICALLY

Snøhvit

„At its peak, there were 2,000 employees on site.“

First successful major contract in Vietnam: KAEFER works with up to 500 fitters on the new construction of a fertiliser factory in Southern Vietnam and is responsible for insulation and scaffolding works.

KAEFER develops the ‘twin bed’. It is made up of a lying surface that is rotatable along the longitudinal axis of the bed. And there is a mattress and bedding on each side, which makes it easy to simply turn over when shifts change.

TYPICALLY

Twin bed

„Extra comfort and no more ‘warmth bonus’.“

A record at KAEFER in South Africa: 3 million working hours without a single ‘lost-time injury’ (LTI) at the SAPREF construction site.

KAEFER sets up a new metal workshop in Scheeßel, near Bremen, which brings several workshops together in one place. This concentrates production capacity for the northern German region in one workshop.

KAEFER takes over the refurbishment and expansion of the old ‘Hafenspeicher XI’ building in Bremen, Germany as well as further extension parts of the Weser Stadium.

KAEFER receives the ‘Apprenticeship Ace’ award as Germany’s best company for apprenticeships from Federal Education Secretary Edelgard Bulmahn.

In March, the company-own Sizani scaffolding training centre opens in South Africa. It is available to KAEFER employees as well as external scaffolders.

KAEFER insulates around 35 km of piping and 2,000 m² of facility space at the Neste oil refinery in Kulloo, Finland with the help of Estonian and Polish colleagues.

Major project in the Middle East: KAEFER undertakes extensive heat, cold and sound insulation as well as scaffolding work at the Dolphin gas project in Qatar commissioned by engineering firm JGC Corporation of Japan.

The ice breaking universal research vessel “Maria S. Merian” is christened. KAEFER is responsible for the insulation of the engines and the complete interior outfitting of the living and working areas through to the wooden decks and kitchen.

60 KAEFER fitters perform extensive insulation work over the course of 18 months at the Allianz Arena in Munich, Germany.

Award from the Karl Nix Foundation in Bremen: a KAEFER apprentice is given the Best Chamber of Trade Examinee prize.

Large scale project in Munich, Germany: KAEFER handles the challenging interior outfitting of the auditorium at BMW Welt, with the highest demands in design and acoustics.

KAEFER acquires Parker in Canada and enters one of the fastest growing markets for insulation and offshore. PARKER KAEFER is market leader in industrial insulation in the region and offers insulation, surface protections and scaffolding services.

Heat technology calculation with KAEFER’s own WTB programme. KAEFER is one of the few companies in the world that also continuously takes part in the maintenance and further development of the complex WTB programme.

Australia: first use of rope access for the “Alcan Gove” maintenance project.

A KAEFER apprentice is awarded Best Insulation Fitter in Germany by the DIHK.

After 14 years, KAEFER is involved with the Alfred Wegener Institute in Antarctica again: interior outfitting, heating and cooling as well as water supply, sewage and plumbing is taken care of by KAEFER at the ‘Neumayer III’ station.

TYPICALLY

Cool solution

„Transport routes of 4,800 km, pack ice, squalls…“

KAEFER Spain receives a contract for the insulation of pipes and valves for the Adriatic Project, the world’s first offshore LNG terminal in the middle of the sea off the coast of Italy.

Acquisition of G+H Schiffausbau GmbH to expand expertise in furniture manufacturing, decorative interior outfitting and gas tank insulation.

Majority stockholding in the British insulation specialist C&D, a leading company on the British market for industrial insulation.

A high performance climatic chamber offers new possibilities: KAEFER invests in a 15m3 climatic chamber that can reproduce temperatures between +120°C und -75°C, whilst being able to modify temperature, humidity and pressure at the same time.

As in the year before, the best insulation fitter is a member of the KAEFER family (apprenticeship exam).

Cold insulation of ADGAS is renewed on “Das Island” in the United Arab Emirates. In one of the most prestigious projects in its history in the Middle East, KAEFER in Abu Dhabi replaces the insulation of around 85,000 m² of piping and tanks, produces and fits 9,000 pipe supports.

KAEFER in Norway receives a contract for the maintenance and conversion of the “Grane” and “Heimdal” offshore platforms. Part of the job includes insulation, paintwork and scaffolding.

KAEFER is on board for the interior outfitting of the largest cruise liners in the world. In Finland, France and the Bahamas with the “Liberty of the Seas”, “MSC Orchestra” and the “Majesty of the Seas”, to name just a few.

„Liberty of the Seas“

The “KAEFER Aids Relief Programme” in South Africa is introduced.

At the Hamburg ‘Elbphilharmonie’ in Germany, KAEFER is fire proofing the steel beams under the striking trapezoidal roof: 6,000m2 of roof surface, 5,000m2 of supporting structure and 1,200 linear meters of flanged connections are covered. The fire protection of difficult connections and transitions are carried out in F 90 or F 120 ‒ an elegant composition in steel and mineral wool.

KAEFER supports the Bremen Chamber Orchestra as the main sponsor.

KAEFER Isoliertechnik GmbH receives BS OHSAS 18001 certification.

The pilot phase of KAEFER’s “PMQ” project management qualification for construction and project leaders begins.

Peter Hoedemaker takes over as Chief Executive Officer from Norbert Schmelzle.

KAEFER employee makes a great performance and comes out on top against 17 other competitors at the European Championship for young insulators.

TYPICALLY

New CEO

„International business & Lean management“

The ‘Woodside Train 5’ LNG facility is finished after two years of construction work. KAEFER in Australia takes care of extensive insulation work in the largest project in the company’s history with a volume of 30 million Euros.

As part of its 90-year anniversary, KAEFER renovates the UNESCO World Heritage upper city hall as a gift to the city of Bremen.

KAEFER in Australia opens a new prefabrication facility for pre-insulated components.

TYPICALLY

90 years

„We’re only strong when we’re together, was my father’s guiding theme.“

As remembered by Ralf Koch

The UN contracts KAEFER in Australia to remove asbestos roofs from UNMit warehouses in Timor-Leste. At the same time, new roofs made of monoclad sheet metal are installed and insulated.

KAEFER wins the ‘Top Areva Supplier’ award from international energy company Areva.

KAEFER Energy in Norwegen gewinnt den Auftrag für alle Wartungsarbeiten in den Bereichen Isolierung, Anstrich, passiver Brandschutz und Gerüstbau auf Statoil‘s Gjøa-Plattform in der Nordsee.

KAEFER is a proud founding member of the European Industrial Insulation Foundation (EiiF) together with 11 other leading companies.

KAEFER in South Africa expands its ‘Sizani Technical Skills Training Centre’ by adding a metal processing school.

The PPP-Project ‘MovIEE’ – ‘Moving India’s SMEs towards an energy efficient future’ starts as cooperation between KAEFER Punj Lloyd in India and the ’Deutsche Gesellschaft für Internationale Zusammenarbeit’ (GIZ).

The Corporate Competence Center Mattresses is founded and bundles the know-how for mattress systems with the insulation of steam and gas turbines.

KAEFER constructs the entire wellness and spa area, including the largest Finnish sauna at sea with room for 54 people on the “Mein Schiff”.

with today’s

innovations

.jpg)

Annelotte Koch, former Managing Director and shareholder, dies in March aged 93.

The start of the Green Car Policy in Germany: in addition to financial considerations, emissions and consumption become criteria for company car choices.

The earthquake in Chile in February affects several employees and their families. Colleagues from around the world help to rebuild lives with their donations.

Premiere of the “International KAEFER photo competition”. Employees around the world submit photos about ‘cultural diversity’. The winning entries feature in the KAEFER annual calendar.

The “Advanced Management Programme” begins for the first time as part of the KAEFER Academy.

The first major project for KAEFER in New Caledonia: KAEFER provides scaffolding for a nickel mine.

The European Championship title and the German Master of Industrial Insulator Technicians title go to a KAEFER employee.

The company headquarters moves to the heart of Bremen on Marktstraße.

A KAEFER apprentice is awarded Best Insulation Fitter in Germany by the DIHK.

KAEFER presents itself to around a million visitors at the communal Bremen stand and the EXPO 2010 in Shanghai. Focussing on ‘Energy Efficiency’, the company shows the benefits of insulation when it comes to environmental protection.

Foundation of the KAEFER Foundation GmbH to support KAEFER employees in emergencies and natural disasters.

The ‘UK Design Scaffold Team‘ is founded. KAEFER in the UK is expanding its portfolio with this independent scaffolding service.

KAEFER in Qatar takes over the corrosion protection for the Dolphin Energy’s ‘DOL 1‘ and ‘DOL 2‘ platforms.

The “KAEFER Code of Business Conduct” is introduced worldwide as a binding code of practice at the KAEFER Group.

Indian research station Bharati, Antarctica: building upon blueprints, KAEFER is responsible for structural engineering, construction, facades and the complete outfitting of the station, including living and working containers as well as the outfitting of the partially prefabricated station at the South Pole.

KAEFER Abu Dhabi receives a contract for the construction of a four-storey hanging scaffold at an 11km piping bridge as part of the ‘Shah Gas development project’.

TYPICALLY

Built on sand

„850 employees work at dizzying heights…“

KAEFER Isoliertechnik GmbH receives DIN ISO 14001 certification.

All aboard on the “Alexander von Humboldt II” and “Rainbow Warrior III” sailing ships. KAEFER is responsible for the delivery and installation of the ship’s kitchen on the 65-metre-long three-mast vessel. Just like on Greenpeace’s “Rainbow Warrior III” – equipped with a galley specially constructed by KAEFER.

Year of action for “Occupational Health and Safety 2012” – the first worldwide campaign launched throughout the company in 13 languages. The five main themes are: risk assessment, training, health, work at height and manual handling. |

|

|

|

|

KAEFER wins the annual ‘Partner of the Year’ award from Meyer Yard for the high quality of its interior outfitting.

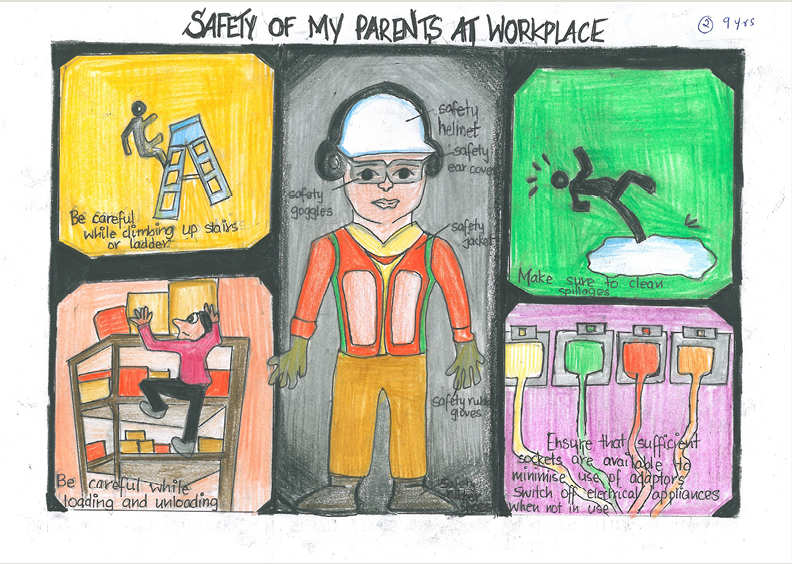

A successful, international drawing competition for the children of employees takes place – the theme is “Health and safety at your parents’ workplace”.

KAEFER in Spain completes a two-year expansion project at Europe’s largest refinery at Repsol in Cartagena: two ten-hour shifts per day, 350 workers, 800,000 hours worked.

The first KAEFER Group sustainability report is published.

The second “International KAEFER photo competition” takes place where the theme is “KAEFER in colour”: 23 countries, 631 fantastic photos and 19 winners.

The Indian Bharati research station is completed on schedule by KAEFER Construction Germany. After 5 months of work, this station is handed over during the Antarctic summer. It is the third polar station that KAEFER has worked on.

This film is in English language.

Fogadtatás! KAEFER opens a new facility in Hungary. The new facility for turbine insulation and mattresses for products such as manifolds, flanges and valves secures KAEFER’s leading position in the mattress insulation market.

TYPICALLY

Bharati

„When the sea starts freezing over you’re stuck for another year.“

First worldwide employee survey at KAEFER with a participation rate of 70%.

KAEFER acquires know-how in passive fire protection through the takeover of Prostar Marine Services in Singapore.

The KAEFER Lean Journey begins with a pilot project on the “Åsgard B” platform in April, which is maintained by KAEFER.

KAEFER in Finland receives several contracts for the renovation of different cruise ships: “Pride of America”, “Legend of the Sea”, “Carnival Sunshine”, “Disney Magic” and “MS Bergensfjord”.

The first ‘KAEFER Trophy’ takes place in Bremen’s Sportgarten, Germany. It combines a football tournament with the presentation of apprenticeship opportunities at KAEFER.

Inspection, maintenance and cleaning work at Dow Chemical Ibérica in Tarragona. KAEFER in Spain provides a major contribution to the project with the build-up and removal of scaffolding, corrosion protection and insulation work. Reaching a height of 116 metres, this is the highest scaffolding tower ever built at a factory in Europe.

Start of an anniversary project: the 25th tunnel in 10 years. KAEFER is responsible for the planning and installation of the fire protection for the E6 road tunnel in Trondheim in Norway.

KAEFER demonstrates its competence at one of Europe’s most ambitious construction projects: KAEFER is responsible for the planning, manufacture and integration of the fire protection of the tower connections at the new headquarters of the European Central Bank in Frankfurt, Germany.

TYPICALLY

ECB

„From the deepest basements to the highest floor.“

At the Sellafield Ltd Supplier Forum 2014 KAEFER in the United Kingdom wins the ‘Going the extra mile’ award in the additional services category.

The third “International KAEFER photo competition” takes place where the theme is “from another viewpoint”. Numerous employees from around the world take part: 478 photos, 197 participants, 25 countries, and 20 winners.

Cooperation between KAEFER Energy in Norway and KAEFER Engineering in Thailand for a module for Statoil‘s “Troll A” platform.

The PACT day, launched throughout the company, officially marks the end of the ‘Year of Quality 2013/2014’. The four focus themes are Planning, Administration, Communication and Technical quality.

KAEFER is responsible for the surface treatment of 57 foundation gravity modules and prefabricated steel modules at the Gorgon gas project, one of the largest gas projects in the world.

Cooperation for the import terminal for LNG in Swinemünde on the Baltic coast. KAEFER employees from Poland and Spain work with colleagues from the Corporate Competence Centre LNG (CCCL) in Germany. Colleagues from the pre-insulation workshop in Australia also help out.

TYPICALLY

One team, one PACT

„The closing events in over 25 countries are as varied…“

KAEFER in Brazil becomes market leader in industrial services and substantial increases market share in South America with the acquisition of RIP Serviços Industriais.

The Neptun Yard in Rostock-Warnemünde, Germany awards KAEFER as its ‘Partner of the Year 2014’.

KAEFER Industrie GmbH in Germany receives an award in the ‘Safety for Contractors’ category at the ‘Bayer Supplier Day’.

Lean Journey: KAEFER creates an environment of continuous improvement, increased efficiency, the establishment of a ‘lean leader’ network and training all around the world with more than 40 projects where lean principles are implemented in 2014.

KAEFER takes part in an initiative of Bremen’s chamber of commerce to help young refugees gain better access to education.

KAEFER Construction GmbH receives a contract for the interior outfitting of the new Audi motor sport centre in Neuburg, Germany.

50 years of Corporate Technology and Research (now Corporate Innovation & Technical Excellence).

KAEFER celebrates 80 years of apprenticeships: the first apprentices stared in 1985 at the family company in Bremen. Throughout this period, 1,352 young people took up an apprenticeship at KAEFER.

TYPICALLY

Research & Technology

„Step-by-step, KAEFER laboratories began to take shape.“

As remembered by Arno Recknagel & Karl-Rudolf Friese

RIP in Brazil secures a further contract with PETROBRAS for the heat insulation at the platforms for Santos Basin, Sergipe und Alagoas.

Within just two weeks in the dry dock, KAEFER in Finland manages to renovate selected areas of the “M/S Finlandia”. The demolition and preparatory work is done during normal operation shortly beforehand.

The tragic earthquake affects over 200 of 1,000 Nepalese KAEFER employees in the Middle East in April. Regional management immediately reacts by establishing an emergency committee to help Nepalese employees to contact families, take time off from work or help directly on the ground. Other members of the KAEFER family help as well.

KAEFER in Qatar receives a contract for fire protection measures at the Laffan refinery from the Consolidated Contractors Company, the largest construction company in the near east.

KAEFER in Kuwait receives a contract for scaffolding work at the ‘Clean Fuel Project’ at the Mina Al Ahmadi refinery from South Korea’s SK E&C.

RIP in Brazil receives an important contract from the insulation of Presidente Vargas Steelworks, which is run by Companhia Siderúrgica Nacional (CSN).

KAEFER in Finland is awarded with a contract for renovation work on the “Norwegian Epic” (photo) and “Silja Serenade” cruise ships.

A KAEFER employee takes second place at the German Championship for Dry Construction Technicians.

KAEFER in Poland is contractor for construction work on the oil refinery in Plock from PKN Orlen.

KAEFER takes part in the state-run incentive programme MobiProEU, as well as ‘The Job of my Life’, which allowed four young people from Spain to begin an apprenticeship as an insulator fitter in Bremen.

A large shutdown in Qatar: Qatar Petroleum’s NGL-3 facility stands still for 21 days. The work done is some of the most extensive ever performed by KAEFER in Qatar.

Introduction

of new products in Norway. ENERGY Products® concentrate on battling the

most important factors and health risks in the process industry: noise,

heat and vibration

www.energyproducts.no

KAEFER in Vietnam receives a contract from TSK Engineering (Thailand) Co. Ltd. for the refractory engineering of the burner at a sulphuric acid facility.

Award from the Karl Nix Foundation in Bremen: a KAEFER apprentice is given the Best Chamber of Trade Examinee prize.

Introduction of the new, global ‘ONE’ Intranet to combine the information from various regional Intranets to form one central platform for collaboration.

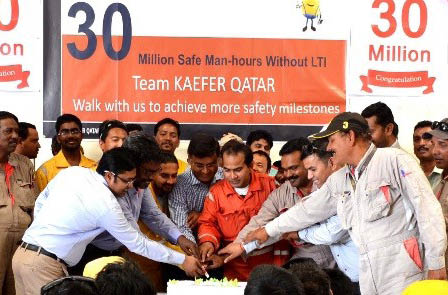

KAEFER in the UAE achieves 30 million man-hours without lost-time injury (LTI).

KAEFER in the Netherlands and Belgium achieves 6 million man-hours without lost-time injury (LTI).

KAEFER WANNER’s first Lean Day takes place on more than 50 construction sites, workshops and offices to present lean principles and KAEFER’s Lean Journey to employees.

The fourth “International KAEFER photo competition” is conducted among employees worldwide, the theme is “leadership in action”.

KAEFER Industrie GmbH’s team in Hamburg is awarded a safety prize from Dow Stade for 24 years and 670,000 man-hours without LTI.

BP Norway awards KAEFER Energy in Norway a new contract for the maintenance of its offshore facilities. The contract extends to all 14 BP offshore facilities at Valhall, Ula, Skary on the Norwegian continental shelf.

The German Champion of Industrial Insulation Technicians comes from KAEFER.

Change of management: Peter Edelmann takes up the position of CEO of KAEFER Group from Peter Hoedemaker at the beginning of the year.

KAEFER in Benelux is awarded the Dow Chemical Benelux Occupational Safety Prize for Subcontractors for the third time.

Extensive scaffolding contract for KAEFER in Sweden for the Preem refinery.

The KAEFER ‘Medupi Scaffolding’ team in South Africa celebrates 5 million man-hours without lost time injury (LTI).

Statoil in Norway awards KAEFER Energy with a new contract worth €30 million for insulation, surface protection and scaffolding at the Mongstad facility.

1,000 employees from 14 countries have already been trained as part of the “KAEFER Safety Culture Training” programme.

A KAEFER employee gets second place at the German Championship for Dry Construction Technicians.

30 million safe man-hours are achieved by KAEFER in Qatar.

RIP Serviços Industriais in Brasil receives a new contract for the construction of a main train station and ancillary work.

KAEFER’s Corporate Competence Center Materials in Bremen is contracted with engineering services and the provision of insulation materials for the “Yamaha Cement Plant Project” in Saudi Arabia.

KAEFER in Malaysia is presented the “Safe Contractor of the Year 2017 Award” by JGC.

The ‘Lean Development Programme’ complements the programme at the KAEFER Academy.

KAEFER in Great Britain achieves one year with over 2,5 million man-hours without lost time injuries.

KAEFER Energy in Norway receives the longest-term contract in the history of the company. Until 2031, it is responsible for insulation, scaffolding/access, surface protection and passive fire protection at Statoil’s offshore platforms.

The Polish Industrial Insulation Technician Championship prize goes to two Polish KAEFER colleagues.

KAEFER in Finland receives a contract from Meyer Turku for a 6,500 m² extension of the public areas on Tallink’s new LNG-powered express ferry, the “Megastar”.

The global “KAEFER Safety Culture Training” programme hits a new milestone: more than 550 employees are trained in Brazil and Peru.

KAEFER in Canada successfully finishes the ‘Cenovus Foster Creek Pipeline’ project with a substantial productivity improvement thanks to applying Lean methods on site – without making any compromises on health & safety or quality.

Lloyds Register Brazil, certifies our subsidiary RIP for ISO 37001. This ISO standard defines rules and procedures to help organisations in the fight against corruption.

KAEFER in Thailand gets safety recognition during its scaffolding maintenance works at Covestro

YASREF awards a five-year maintenance contract for insulation and scaffolding works at its 5.2 million square meter large oil refinery in Yanbu to KAEFER in Saudi Arabia.

Start for KAEFER new digital project at the Kårstø processing plant in Norway. KAEFER Energy is testing how the use of web solutions and tablets can streamline selected work processes at the Statoil-operated facility.

The "Symphony of the Seas" conquers the oceans. KAEFER WANNER in France performs interior outfitting works on the largest ocean liner in the world.

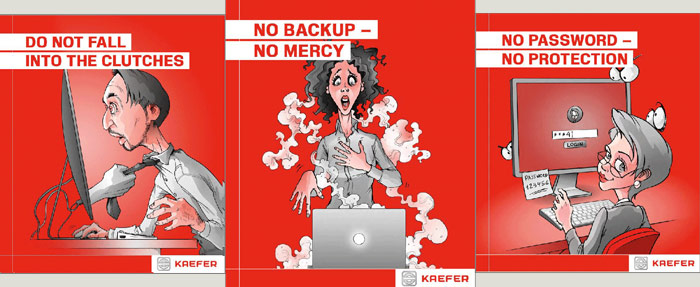

The global IT security awareness campaign covers topics around back-ups, password security, data access, alertness, updates & social engineering.

KAEFER Energy in Norway enters an operational alliance with Aker BP and will undertake the execution of insulation, surface protection, scaffolding and access as well as interior outfitting and HVAC on all installations of Aker BP on the Norwegian continental shelf.

KAEFER in Saudi Arabia achieves 35 million man-hours without LTI. The high commitment towards safety and the ongoing promotion of a positive HSE culture pays off thanks to everyone’s effort, support and dedication.

Across the year, many KAEFER locations are celebrating the 100th company anniversary. Employees in Norway, Brazil, Australia, Germany or in the Middle East are coming together to look back on the last century and to look forward to the next.

More than 80 KAEFER colleagues gather together for the 5k BMW company run in Bremen to support a well-construction project in Uganda and celebrate our 100-year company anniversary.

Two teams of KAEFER come in second and third place at the FESI European Insulation Apprentice Championship.

KAEFER in Malaysia secures a new order from Sapura Energy for supply and application of thermal & noise control insulation material for pipes, fittings, mechanical and static equipment for a new high density polyethylene plant at the Petronas RAPID petrochemical complex.

New Code of Business Conduct for the KAEFER Group worldwide: Our anniversary is the perfect occasion to take our Code of Business Conduct into the next century by updating it with contemporary topics that have become increasingly relevant to all of us.

The fifth “International KAEFER photo competition” takes place, the theme being “Living our values”. Numerous employees from around the world take part: 401 photos, 159 participants, 20 countries, and 20 winners.

KAEFER Isoliertechnik GmbH & Co. Kommanditgesellschaft reaches an attractive placement of senior secured notes resulting in a refinancing schedule for a running time of 5.5 years, in an amount of 250 million EUR, with approx. 50 investors. KAEFER also extends its syndicated loan including guarantees for another 5 years to allow enough headroom to continue developing its business successfully.

Premiere for the KAEFER Future Award: Leander Stützel of the University Augsburg wins the prize worth 5,000€ for the ’development and thermal optimisation of porous light clay building material’. For the first time, KAEFER awards an outstanding project from the areas of material research or insulation just to name a few. Laura Marie Henning of the TU Berlin came in second place, her project that researches new ways to purify water on an industrial level will be supported by the KAEFER Foundation.

Dr Roland Gärber, former COO, and Steen E. Hansen, former CFO, take over the management of KAEFER as Co-CEOs and constitute the Executive Board.

The German Chamber of Industry and Commerce awards the 200 best apprentices in their profession. For the first time, a female (KAEFER) insulation fitter is announced winner in this category.

The HSE team of KAEFER in Malaysia receives the ‘Focused Recognition Award’ from PETRONAS for the Samsung RAPID 6A project.

KAEFER KOSTEC in Peru applies extensive fire protection coatings to the stadium structures for the Pan American Games in Lima 2019.

The KAEFER FOUNDATION hands over the donations collected for the 100th anniversary to the "Gesellschaft zur Rettung Schiffbrüchiger (DGzRS)", the "Bremer Krebsgesellschaft e.V." and the "Kinderhospiz Löwenherz e.V.".

KAEFER in Poland produced a film, whose hero is one of their employees: Henryk Karwowski experienced a work accident in September 2018. He decided to share his story to raise awareness and motivation among all colleagues to wear proper Personal Protection Equipment (PPE) at all times – as it saved his life and health last year.

KAEFER Montage GmbH in Germany receives the TOTAL Safety Award 2018.

Equinor, one of the largest offshore operators in the world, awards KAEFER ENERGY in Norway a contract worth millions on the Johan Sverdrup oil platform.

KAEFER in Kuwait achieves six years and four months with over 10 million man-hours without lost time injuries.

The SAGA Group chooses KAEFER Construction in Germany once again for the complete refurbishment of its 335 residential units (8 million turnover). With around 130,000 apartments and about 1,400 commercial properties, the housing company is the largest renter of Hamburg.

KAEFER organises an international Compliance Video Competition. More than 200 participants from all over the KAEFER world submit videos showing how they support Compliance at KAEFER.

KAEFER Industrie Germany receives the DOW Safety Award 2019 for 771,835 man-hours over 26 years of excellent, safe and accident-free work.

The KAEFER team from Poland takes second place at the Polish Championship of Industrial Insulators.

KAEFER Energy in Norway receives the Lean Award 2019 at the Lean Network Conference in Norway.

KAEFER Construction in Germany is awarded a € 9 million contract for the interior finishing of the "Forum Steglitz" shopping centre in Berlin.

KAEFER Construction in Germany is awarded a € 9 million contract for the interior finishing of the "Forum Steglitz" shopping centre in Berlin.

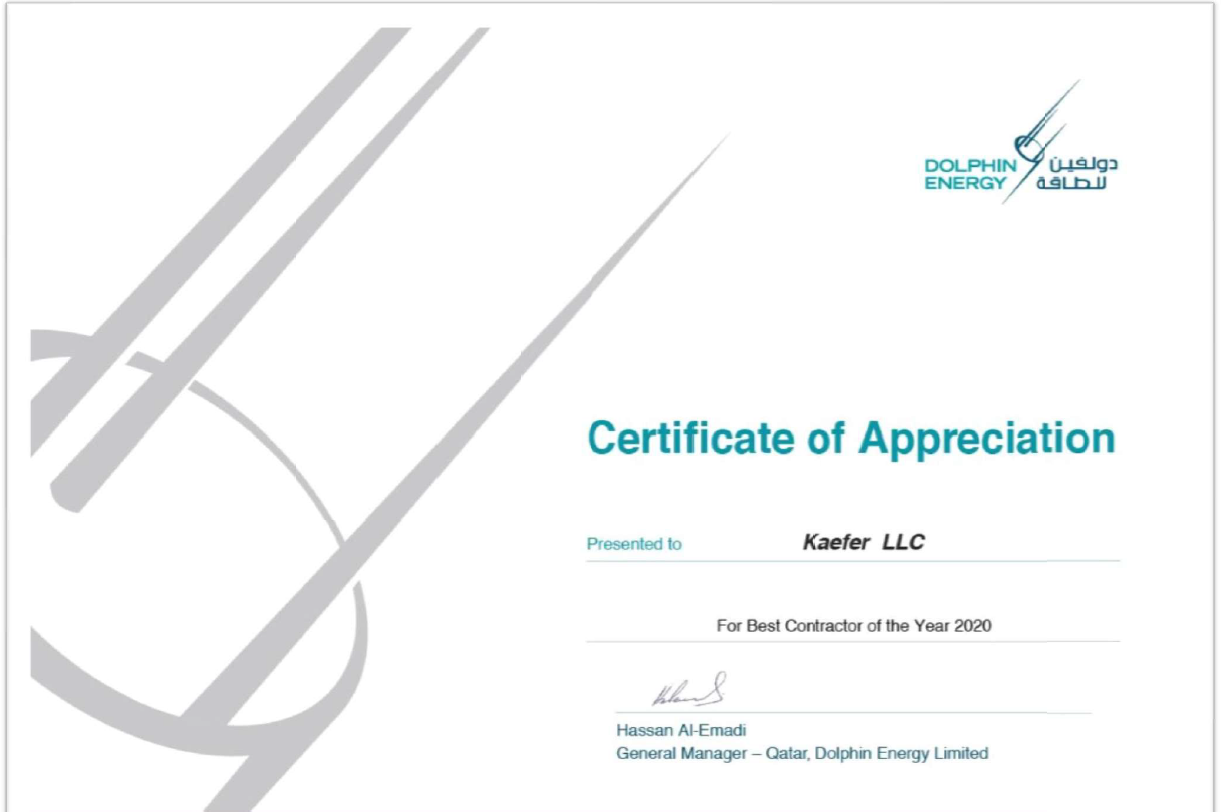

KAEFER in Qatar is honoured as "Best Contractor of the Year 2018". It is the first time that the prize is awarded to a non-mechanical company.

As the first apprentice at KAEFER, Thomas Oldsen receives the awards for best insulation worker and industrial insulator in Germany.

The KAEFER FOUNDATION supports a registration event against blood cancer, at which 56 employees from the Headquarters and the branch office in Bremen are registered as potential stem cell donors.

KAEFER launches its new image film.

KAEFER in Poland is awarded as an "Young Worker-Friendly Employer".

The Bahwan Engineering Group awards KAEFER in Oman a major contract for large-scale pipeline Insulation work at the Duqm refinery.

KAEFER acquires Wood's Industrial Services Business in the UK and Ireland.

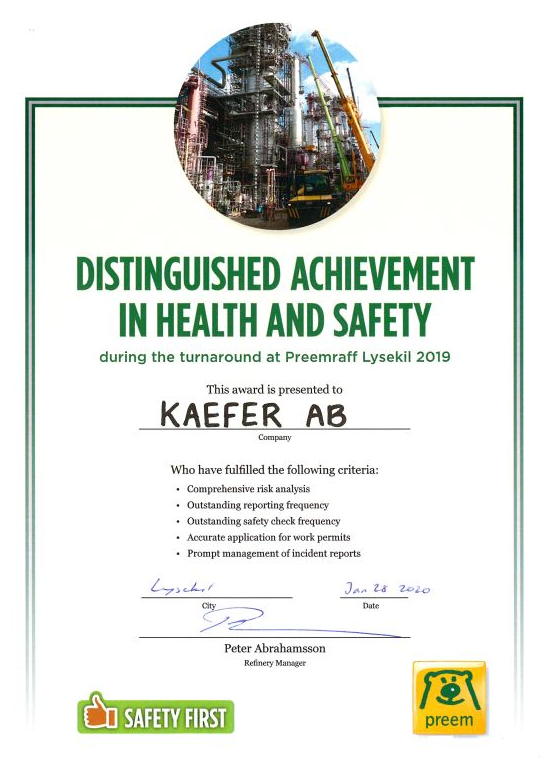

KAEFER Sweden is awarded a diploma from Preem for the safety work during the turnaround at Preemraff Lysekil 2019.

The team from KAEFER KOSTEC in Peru wins the third "Fantastic Scaffolding Contest" organised by Layher.

KAEFER Construction in Berlin receives Rigips Trophy for the best performance in the category "Acoustic Systems".

KAEFER Energy receives a new maintenance contract by Equinor. The agreement represents several billions in sales for KAEFER Energy during the term up to 2031 and will engage up to 500 employees.

KAEFER launches a global poster campaign on alcohol and drug abuse.

The first digital version of the Sustainability Report is published.

The new KAEFER FOUNDATION section on the global KAEFER website is launched. Designed with a fresh look in line with the updated design of the foundation, it provides an overview on the mission and fields of activity.

KAEFER in Sweden received a major maintenance contract for insulation and scaffolding works from Borealis, a leading international provider of polyolefins, base chemicals, and fertilizers.

KAEFER in UK & Ireland is awarded the SC21 Gold, given for LEAN manufacturing and efficiency in the Aerospace and Defence Market.

KAEFER and VDI celebrate 50th anniversary of funding membership. The VDI - Verein Deutscher Ingenieure e.V. (Association of German Engineers) provides important impulses for new technologies and technical solutions. With around 145,000 members, it is the largest technical and scientific association in Germany.

KAEFER in Belgium wins BASF Antwerpen Safety Award 2019.

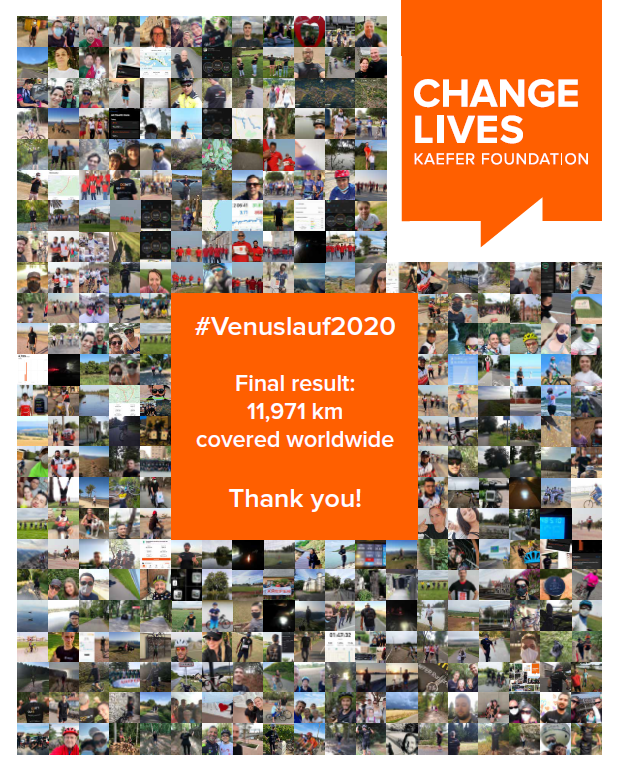

On 20th September 2020, hundreds of KAEFER employees around the world join the so-called "Venuslauf" to raise funds in the fight against cancer. On their own, but close together, fantastic 11,971 km were covered by running, walking and cycling!

KAEFERs Co-CEOs Dr. Roland Gärber & Steen E. Hansen sign CEO-letter to European Commission to support he request to raise the EU 2030 emissions reduction target, the European Green Deal and a more climate-resilient and regenerative recovery of EU in response to the impacts of the Covid-19 pandemic.

KAEFER in UK & Ireland secures £90 million Industrial Services Framework contract renewal with Sellafield Ltd. The awarded framework extends the long-term relationship and will deliver a range of Industrial Services in Cumbria, including access, insulation and asbestos services.

KAEFER Industrie GmbH in Leipzig receives a framework contract from TOTAL Raffinerie Mitteldeutschland GmbH with a volume of € 10 million..

KAEFER in Qatar gets recognised as "Best Contractor of the Year 2020" by the long-standing client Dolphin Energy.

Let's go digital! For the first time the yearly published magazin K-WERT is purely digital. Take a look and dive into various stories from the KAEFER universe.

KAEFER in Benelux receives the EH&S Contractor Award from the client DOW Benelux B.V.

KAEFER in the UK & Ireland strengthens partnership with Wood by entering into a three-year agreement to deliver industrial support services at Equinor's Mariner field. The agreement will run for three years.

KAEFER in the UK & Ireland wins significant contract for major ductwork fabrication works for the new nuclear power station Hinkley Point "C" in South West England

KAEFER Engineering Ltd. Thailand achieves certification of Green Industry.

The KAEFER FOUNDATION supports three charitable organisations on the occasion of the World Environment Day. Explore all inspiring initiatives here!

KAEFER S.A. (Poland) wins Layher competition award.

The 10th edition of KAEFER's Sustainability Report is published. Enjoy discovering!

KAEFER in Belgium secures important framework agreement for all Belgian nuclear power plants.

With the support of the KAEFER FOUNDATION KAEFER employees raise funds for the people affected by the flood disaster in Germany in mid-July 2021.

The KAEFER values get a new look to further support the way of communicating the focus on strong values and continuity across all entities, countries and regions and to embrace the diversity of those we work with.

And we did it again! Between 17th and 19th September 2021, 1,500 KAEFER employees around the world joined the Venuslauf demonstrating the KAEFER team spirit and raising funds in the fight against cancer. Walking, running, biking, skating, surfing and canoeing - a total of 23,904 km covered.

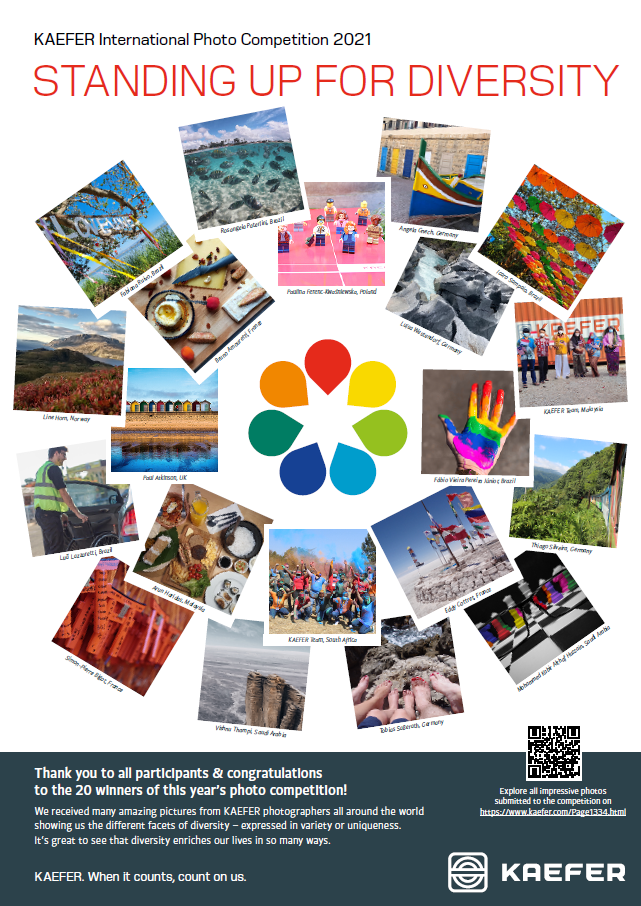

The sixth "KAEFER International Photo Competition" takes place. Numerous great entries from all around the world on the topic of diversity are submitted.

KAEFER in Malaysia receives a Certificate of Appreciation by our longstanding customer Toyo Engineering & Construction Sdn Bhd. for achieving 500,000 Manhours without LTI on the "Black Condensate & Heat Integration Project".

KAEFER in Benelux reaches milestone of 3,000,000 hours worked without lost time due to injury (LTI).

The newest edition of K-WERT is published. Dive into our magazine about people, projects and stories from the KAEFER universe. Grab your laptop, tablet or mobile and explore interesting articles!

Five years after its launch, our global intranet "ONE" is getting an upgrade: "ONE.2" will be based on MS SharePoint Online, which offers many new possibilities and breaks down barriers.

KAEFER enters into a partnership with the Germany based SMS group (‘SMS’) and the European PE-fund Altor Fund V (‘Altor’) domiciled in Sweden, who, together, become a 50% shareholder in KAEFER. The new shareholders will partner with the current KAEFER shareholder family who will continue to hold the remaining 50% in KAEFER.

The KAEFER Sustainability Report 2021 is published. The 11th edition describes the progress we have made in integrating environmental protection, social responsibility and good corporate governance (ESG) in our entire value chain.